At some point everything will come together and what is a concept now is likely to become a serially produced product. Or at least elements will

By Gary S. Vasilash

The BMW M Visionary Materials Seat—designed by BMW Group Designworks with the BMW design team; supported by Automotive Management Consulting GmbH, Bcomp Ltd, Gradel Lightweight Sàrl, and Lasso Ingenieurgesellschaft mbH—was recognized in the Sustainable Process category in the Altair Enlighten Awards presented last week during the 2024 Center for Automotive Research Management Briefing Seminars.

And some of you have probably already seen it and are thinking that I’m slow to the draw here.

I wanted to get a bit more info on the seat, about which Falco Hollmann, Innovation Manager Lightweight Design & Sustainability at BMW M GmbH, said: “We are showing today what will be possible tomorrow with existing technologies and materials in order to take our efforts to reduce emissions and conserve resources to the next level. This is about more than just substituting materials; it is above all about designing for circularity.”

Many reports have it that it doesn’t have a support structure, which may make it sound like it is, well, floppy. Which wouldn’t be particularly effective as a seat.

Although it doesn’t have a conventional seat structure, it does have structural elements.

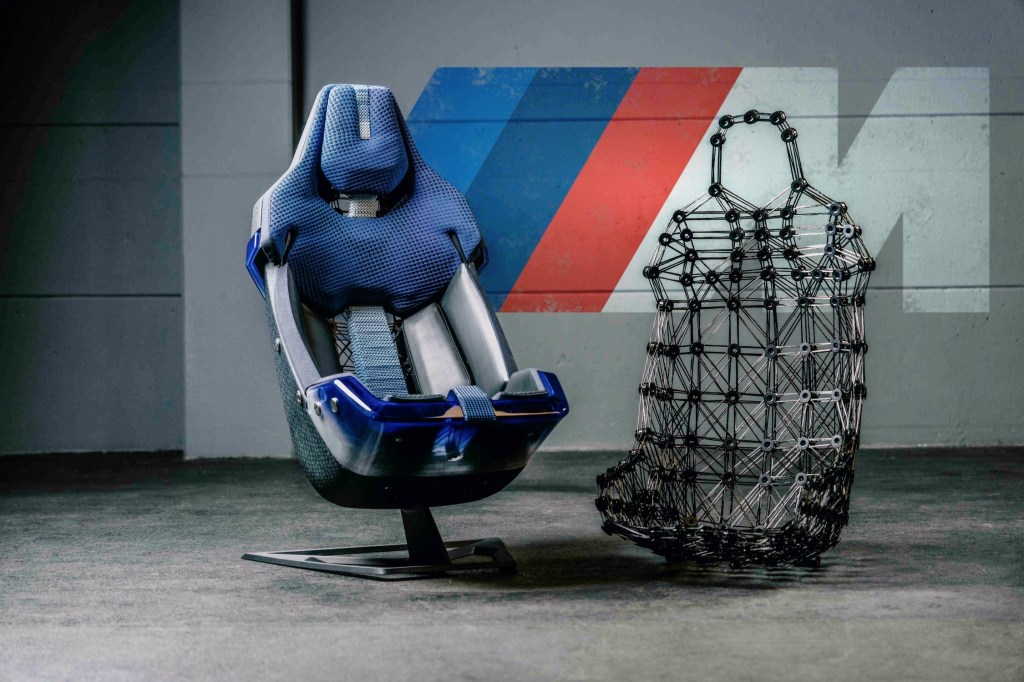

For example, there are robotically wound fiber composite elements (the black stick-like pieces on the object on the right of the photo) that form a load-carrying core structure.

Then there is the blueish/white mesh structure that you can see on the left side of the photo in the center part of the seat, which, according to a BMW spokesperson, is “made from a soft, gel-supported (reusable) structure from an additive manufacturing technology.”

(That is not a cutaway of the seat. It is designed with a minimalist approach so that foam component is visible.)

One of the things associated with the development of the seat is LCA: life cycle assessment. From start to finish—and beyond.

There is another factor taken into account, something less familiar than LCA: SQR.

That’s “secondary raw materials quota.”

A goal was to use materials that would go on to have a post-seat useful existence without additional processing steps (as would be the case with typical recycling), which led to the deployment of natural fibers, fiber composites, leather alternatives and algae-based polymers.

One of the important aspects of the development of the seat is the learnings obtained that can be applied to things that aren’t merely concepts.

Roberto Rossetti, Head of Development Total Vehicle-Lifecycle at the BMW Group:

“One of our biggest lessons was the balancing, in other words, how to model our process chain to generate missing primary data. The data obtained provides new insights, both in terms of today’s negative contributing factors and the design of tomorrow’s processes. This experience provides a solid foundation for continuously improving sustainability and developing innovative solutions for forward-thinking mobility.”